A visit to the factory where all goggles carrying a Scott logo are manufactured.

Gear

Under the hood

Made in Austria: A visit to the Scott goggle factory

We’re in Mattighofen, a small town half an hour north of Salzburg in Upper Austria. The place has a surprising variety of industrial production, most prominently from motorcycle brand KTM. However, I’m at a different factory that is less known and many people wouldn’t expect to be situated in Austria. Its name is Scott GmbH, and it produces all goggles for the Scott Sports brand—and has done so for several decades. Interestingly, the factory isn’t part of the Scott Sports conglomerate, but has remained an independent entity since it started to produce goggles exclusively for the Scott brand in the 1980s.

The story how this came about deserves its own article—one that will be written another time. In any case, it’s clear that not too many people are aware that all Scott googles are actually “Made in Austria.” To change this, Scott GmbH and Scott Sports decided to arrange a factory tour for a select crew of people, among them Scott athlete Valentin Rainer. Downdays tagged along to check it out.

Whenever I get the chance to visit a production facility, I’m curious to sneak a look behind the glitzy scenes of our sport. After all, the ski world is comparatively small-scale despite all the glamour involved, and oftentimes companies come up with creative solutions, clever ideas and lots of dedication in order to produce the high-quality equipment that all we have become accustomed to. Goggles may seem like a rather simple product compared to skis and bindings, but as it turns out, there are many more steps involved in finishing the product than one might think. It shares many challenges with the production of other ski equipment like, for example, boots.

A few key takeaways upfront: There’s still a surprising amount of handwork involved in the production of goggles. The quality of a goggle depends on many small, rather unglamorous details, even though marketing mostly focuses on flashy technology and materials. There are surprisingly few materials used in the production of goggles, which makes them a product that is very well suited for recycling.

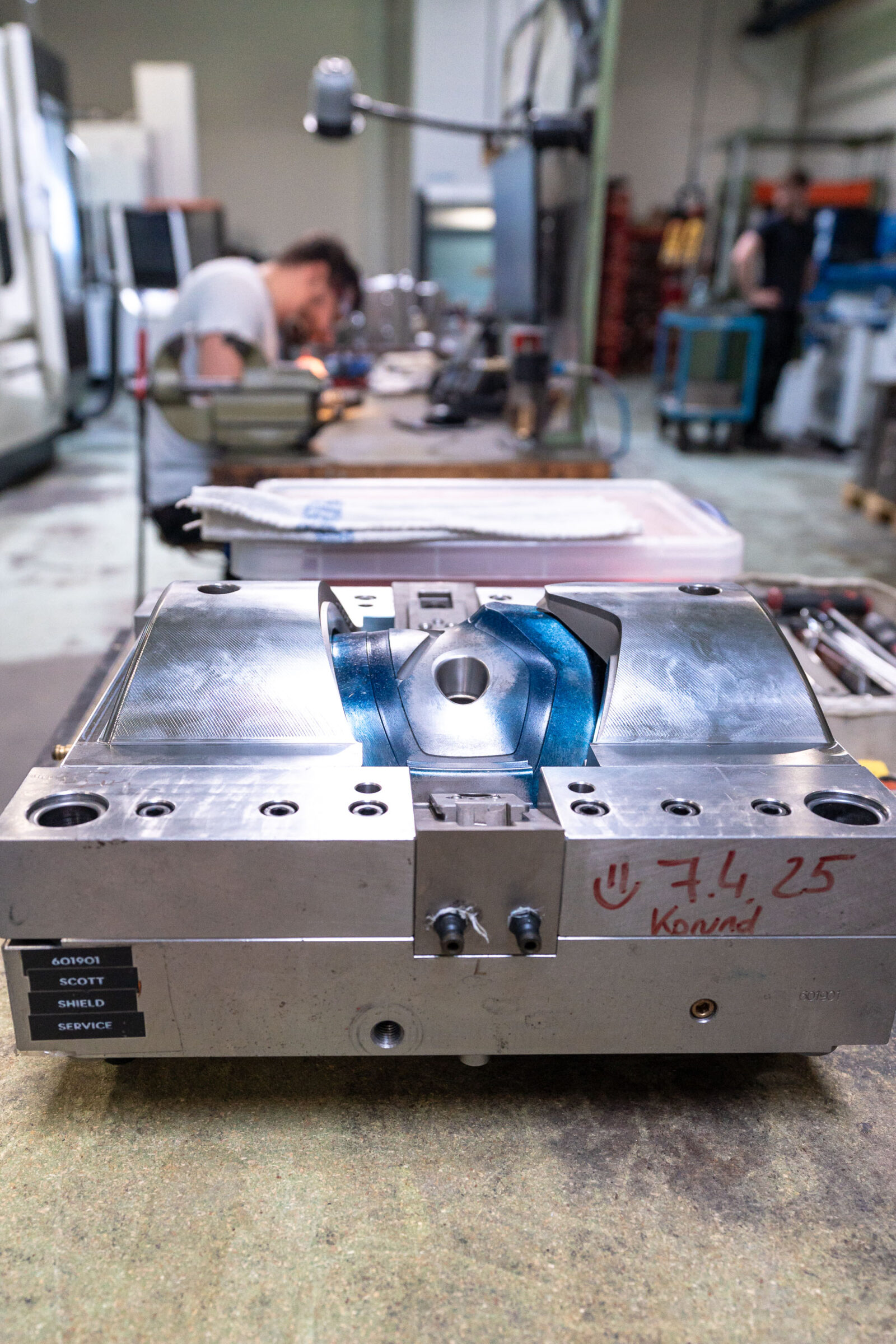

But let’s get started with the factory tour. At the beginning of production stands the most expensive and most time-consuming step. Like most plastic parts, goggle frames are made with injection molding. That means that molten plastic material gets injected into a hollow mold, where the plastic is cooled down into its solid state and the result is the final frame. Sounds simple, and it actually is in the final production process, when a frame takes about one minute per piece. You need the hollow mold, though, and that is what costs time and money. The molds are designed in CAD and then sculpted from metal, a process that is easier said than done due to the rather finely structured goggle frames. It’s a key competence of Scott GmbH and has been even before they started to produce goggles. In fact, a sister company still makes all kinds of plastic products for the automotive or the medical industries. But at Scott GmbH, the focus is exclusively on goggles for the Scott brand.

Once the goggle frame has been made, a lot of small steps need to be taken in order to get a pair of goggles as we know it, and most of these steps involve crafted handwork. For example, foam needs to be glued to the frame, both where the frame touches the face and where ventilation needs to be covered. Due to the finely sculpted forms of goggles—different from model to model—these processes cannot easily be automated. The number of goggles produced is simply not high enough to make the investment in the required machines profitable. The same goes for the process of cutting and sewing the goggle straps, not to mention threading the straps to the frames.

Nevertheless, Scott GmbH has come up with quite a few clever solutions that make the workers’ lives much easier and therefore more productive. That’s why Scott goggles are still “Made in Austria,” and not somewhere in Asia—which is the case for most of their competitors. It should be pointed out that these clever solutions and detailed improvements are self-engineered and stem from perfecting the production process over decades. For example, when sewing badges onto straps, workers only need to cautiously place the strap and badge at the sewing machine. The sewing itself is automated, since it always follows the same simple path.

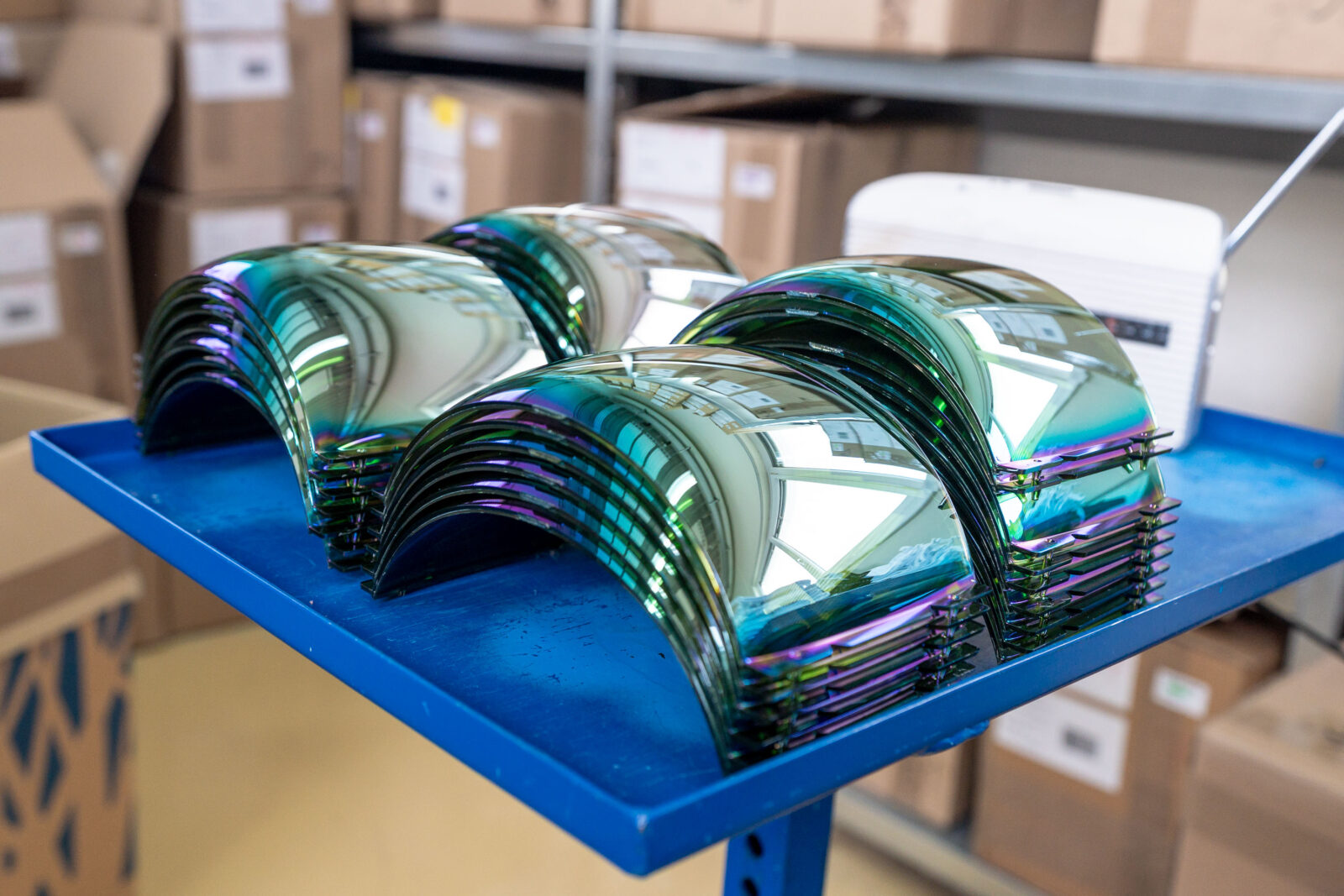

The other major ingredient for a goggle is, of course, the lens. Despite what marketing of many goggle brands wants to make us believe, the optical quality of the lens material is mostly the same for each google—at least of the ones that are quality products from established brands. The reason is simple: The process of tinting the lens plastic and applying the coatings—which block UV radiation, for example, or reduce fogging—are highly technical processes performed by very few big players of the chemical industry. Goggle brands buy the lens blanks from these companies, meaning the base quality of most lenses are the same.

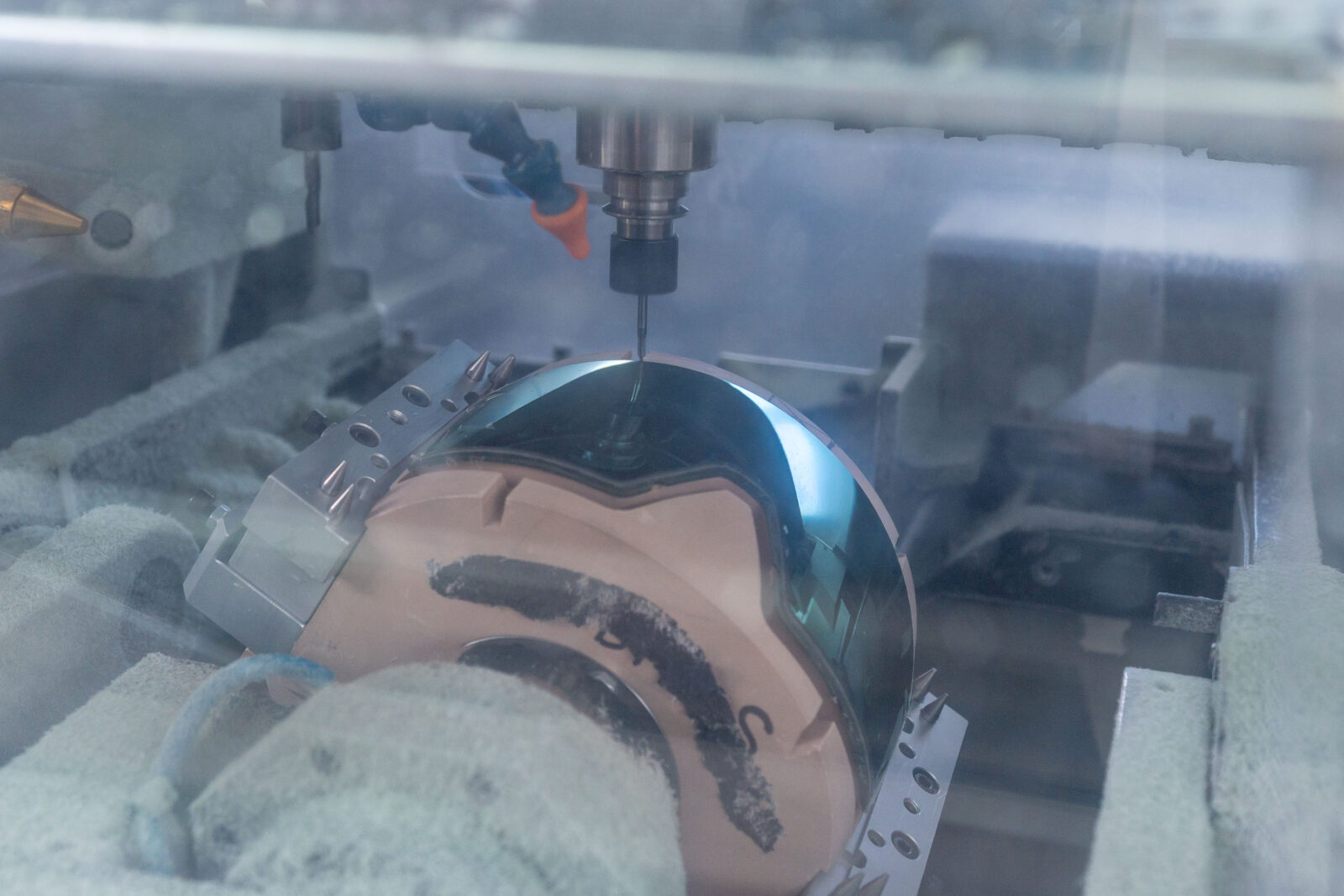

What matters, though, is how the lens blanks are further processed to fit the specific goggle frames and how the goggle is generally designed. Every lens has the optical quality of light refraction, which varies depending on the angle with which light hits the lens. A good goggle design needs to make sure that light hits the lens as uniformly as possible across the whole lens, while also keeping the lens close to the skier’s face. The process of machining the lens blank into form according to the goggle design is performed by high-quality, automated grinding machines and may require a different amount of runs, which in turn effects the production cost.

An interesting side note from experts at the Scott factory: The optical quality of a goggle lens depends vastly on the tint and the invisible coatings applied to the lens material. The fancy metal coatings, however, which cause the mirror effect and create a silver, rainbow or similar shade, are more of a fashion item and don’t really contribute to the optical quality. They require, of course, an extra production step—a quite expensive one.

When the finished lens and equipped frame are combined, a finished product has been achieved. It’s not the end of the process at Scott GmbH, however, since every google gets tested before leaving the factory. They test not only the light transmission, but also the symmetry of the goggle. If the frame or the lens is off-axis, light won’t hit the lens (and consequently the customer’s eye) as intended, resulting in inferior performance. A pair of Scott goggles will hit the market only after proving its quality at a test stand.

Finally, it’s worth mentioning that Scott GmbH has a strong focus on sustainability. Since plastic needs to be heated up into a molten state for injection molding, the production is quite energy-intense, but most of the energy consumed is produced by solar panels on top of the factory building. All plastic production leftovers are recycled into the same process, so that basically all plastic that enters the factory building leaves in form of a google, and materials are selected such that a major part of the goggle can be recycled after its life cycle. In fact, even though the foam glued to the plastic frame looks completely different, both are made from the same base material, and can therefore be recycled together.

There you have it: All the steps involved in producing a pair of goggles. It’s more than you might expect, and most interestingly it’s a lot of small details that you don’t think of which determine a goggle’s quality. Surely, a quality goggle can also be produced in a different place, but having the production facility in Austria, enables Scott to move forward quickly with new designs and product improvements. Not to forget that many of the workers at the Scott factory have been with the company for many years, helping to keep quality standards at the highest level. So next time you’re shopping for a pair of goggles, maybe consider where they are made.