Gear

HighlightBack in black

Phaenom Footwear: The New Kicks on the Block

It’s not every day that a new ski boot company makes its debut, much less a company that’s focusing specifically on the freeski market. In fact, the last one we know of was Full Tilt Boots, all the way back in 2006.

So when the rumor mill started murmuring that Full Stack Supply (the parent company of Faction Skis) was working on a boot brand, ears immediately began perking up in the ski community.

After several years of said rumors, the cat is now officially out of the bag: Two models of Phaenom boots (that’s pronounced fay-nom) are now available for purchase in Europe as part of a limited drop ahead of the brand’s planned global launch in 2024.

The FS 120.

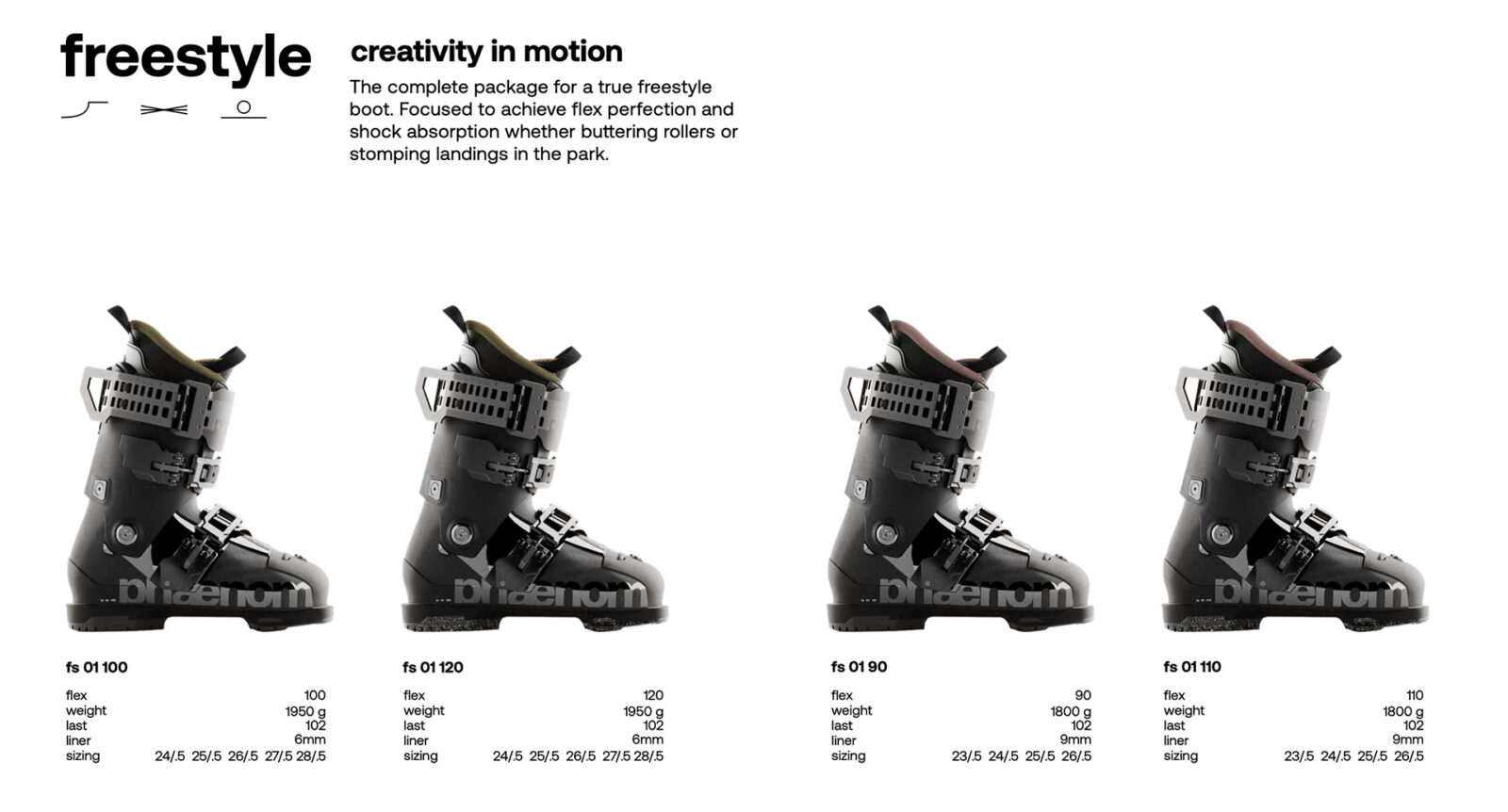

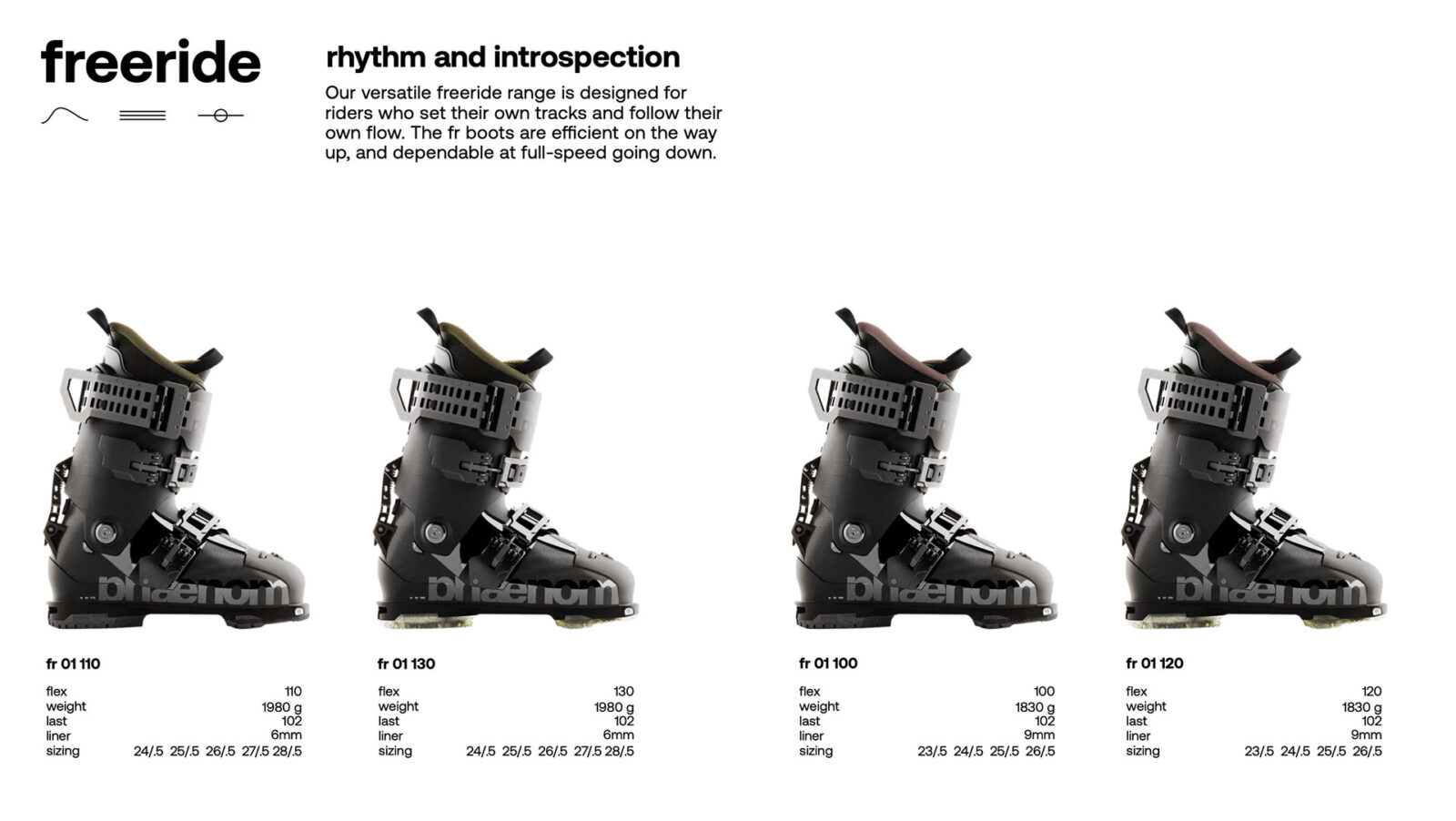

Phaenom’s debut collection features a freestyle-oriented boot and a touring-ready freeride boot, each available in four different flex ratings. The freestyle boot runs from a 90 to 120 flex, while the freeride boot goes from 100 to 130.

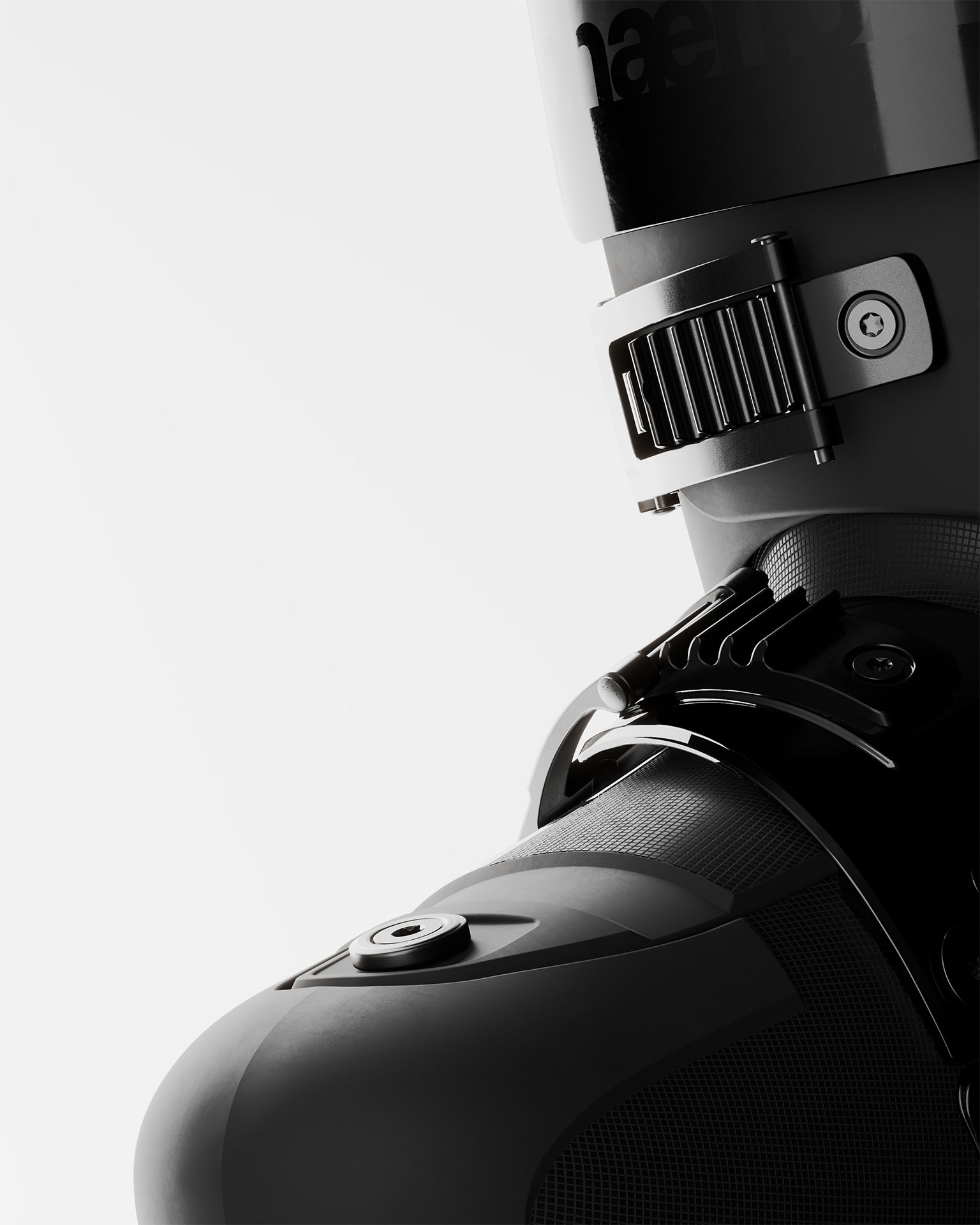

At first glance, some of Phaenom’s design priorities are immediately evident. The biggest eye-catcher is the wide “Phaenom strap," which, according to the brand, provides “rebound, shock absorption and flex control from a single recyclable material.” They’ve also opted for the 3-piece “cabrio” design beloved by many skiers, with a tongue that helps modulate the boot’s flex while allowing for easy entry. A two-buckle concept and an unassuming all-black design round out the first impression.

Underneath the hood, however, is a design philosophy intended to reduce the boots’ ecological footprint. Every individual part, from panels and buckles to straps and screws, is designed to be repairable and recyclable. Even the all-black look, the brand says, is intended to “support restoration and reuse of the boot and all its parts.” It’s all part of Phaenom’s stated mission to “catalyze the transition to circularity”—that is, to build a production model that emphasizes reuse, refurbishment and recycling of components to the greatest extent possible.

As for now, Phaenom’s first limited drop is exactly that: limited. Only the 120 freestyle boot and the 130 freeride boot are currently available—the former at phaenom-footwear.com and select retail partners, and the latter only at selected shops, not online. The available sizes are constrained to the 25-26.5 range for now, and the limited release is only available in Europe.

In Interview: Daniel Tanzer

With this much-hyped brand making its long-awaited debut, we wanted to find out a bit more about the boots and their development. Daniel Tanzer, Phaenom's Head of Hardgoods, was willing to answer a few of our questions.

Downdays: It’s not every day that a new ski boot brand comes out. What does Phaenom bring to the market that wasn’t there before?

Daniel Tanzer: It’s the special combination of four key pillars: stylish, practical, comfortable, and cyclical. We’re offering a performance product with a very comfortable fit, emphasizing repairability and recyclability, and coming with a true design aesthetic. There are some literal answers to this question, like the all-black color supporting restoration and reuse of the boot and its parts, and the patent-pending Phaenom strap providing rebound, shock absorption and flex control from a single recyclable material. But each specific feature is part of this matrix: stylish, practical, comfortable and cyclical. This is something that when taken together brings a unique perspective and offering to the market.

What were the priorities of the team when designing the boots?

We set out to create new ski boots because we saw a gap in the market for a performance freeski product that was at once circular and design-driven. The trends were going towards mass-market, four-buckle overlap and super-light touring. For us, freeski is about fun, excitement and versatility. ‘There’s got to be something better for freeski,’ that was a key driver for us. What we’re most proud of is that our approach, in collaboration with footwear experts from Innsbruck, Paris, Asia and Montebelluna, aims to accelerate the transition towards circularity in outdoor footwear. Each element of these boots—from panels to buckles to straps and screws—is designed to be repairable and recyclable. This ensures a longer lifespan for your boots, as well as circularity following the products’ end of life. Our goal at Phaenom is to pave the way for the future of product design.

Did other boot molds or concepts serve as a starting point for the phaenom designs, or did the team start from scratch?

Ski boots have come a long way since the introduction of the first all-plastic ski boot in 1960. We have seen various innovations in design and technology and ski boots have evolved significantly. In 1979, Eric Giese and Al Gross, a former NASA engineer, collaborated to create one of those most pivotal innovations in ski boot design: Giese was inspired by the joints of spacesuits and designed a ski boot with an additional tongue that was meant to control the boot's flex. This design was named the Flexon, also known as the 3-piece or Cabrio design.

We were inspired by the 3-piece design and set out to enhance this concept with modern technology and materials, innovative design, and the emphasis on circularity. Our boot mold is 100% original and unique to phaenom, four years in the making. We are delivering the next evolution of the tried and true 3-piece boot.

We first heard rumors about this brand a few years ago. What were some of the challenges involved in bringing Phaenom to market?

We think of it less as a "challenge" and more as a reality. Bringing a new brand and product to market simply takes time. It’s impossible to imagine spending fewer than four years of intensive R&D to bring a new ski boot to life. There were times that we may have been tempted to release the boot, but the wait was worth it to ensure that the boot is 100% ready for demanding freeskiers.

One significant challenge that cannot be overlooked is to produce a product with truly circular qualities that is also of the highest-performance caliber. It took us four years to achieve this proper combination, and that’s also something we are proud of.

What can consumers expect from the brand now and in the future?

We have a saying: the first loop starts here. The limited drop of our freeski boot collection is only the beginning for us. We are a footwear company. Technical mountain footwear is at the heart of what we do today and what we will always work towards. In what future forms our visions will come to life, that is something you will have to just wait and see.

What kind of liner does the boot sell with?

The boots feature a new, in-house-developed liner with cutting-edge features. For example the liner may be laced for customizable fitting and is designed with a strong emphasis on sustainability. Its unique outer sole is designed to absorb high and low frequency vibrations coming up through the ski boot, making repeated landings more comfortable and reducing foot and leg fatigue throughout the day. The sole’s extra grip and design means it's tough enough to be worn alone at après, or on your journey to and from the ski hill. It’s made from a minimum of 50% bio-based content.